The global supply chain is in a constant state of flux, and for the past decade, one country has consistently emerged as a star player: Vietnam. For Small and Medium-sized Enterprises (SMEs) in the US and Europe, Vietnam presents a golden opportunity—a potent combination of competitive pricing, improving quality, and a stable manufacturing environment.

But let’s be realistic. Navigating this dynamic market from thousands of miles away can be daunting. Where do you start? Who can you trust? How do you ensure your product arrives as specified, on time, and on budget?

This comprehensive guide is your A-to-Z playbook. Drawing from over a decade of on-the-ground experience, we’ve distilled the entire sourcing journey into a clear, actionable 7-step process.

Step 1: Foundational Research & Product Validation

Before you even think about suppliers, you need to do your homework. Not all products are a perfect fit for Vietnam’s manufacturing landscape. Vietnam’s strengths lie in key areas: Furniture & Home Goods, Garments & Textiles, Footwear, Agriculture, and a rapidly growing Electronics sector.

Actionable Insight: Check how trade agreements like the EVFTA (EU-Vietnam Free Trade Agreement) and CPTPP can benefit your specific product through reduced tariffs. This research can give you a significant competitive advantage.

Step 2: Supplier Discovery & Qualification

Finding a supplier is easy. Finding the right supplier is the hard part. This is where most sourcing mistakes happen. After identifying potential partners through online platforms, trade fairs, or industry associations, the critical vetting process begins. You must differentiate between a legitimate factory and an unreliable trading company.

How to Qualify Suppliers (Vetting):

Once you have a shortlist, ask for:

- Business License & Certifications: Verify their legal status and check for quality certifications like ISO 9001, FSC (for wood), or OEKO-TEX (for textiles).

- Factory Audit: If possible, a physical or virtual factory audit is non-negotiable.

- References: Ask for references from other clients in the US or EU.

This rigorous vetting process is crucial but can be incredibly time-consuming. This is often where a sourcing partner’s established network of pre-vetted factories becomes a major time-saver.

Step 3: Request for Quotation (RFQ) & Sampling

A detailed RFQ is crucial for receiving accurate pricing. Your RFQ should include detailed product specifications, technical drawings, packaging requirements, order quantity, and target price. Once you receive quotes, shortlist 2-3 suppliers for sampling. The “golden sample” will become the benchmark for quality control during mass production.

Step 4: Negotiation & Contracting

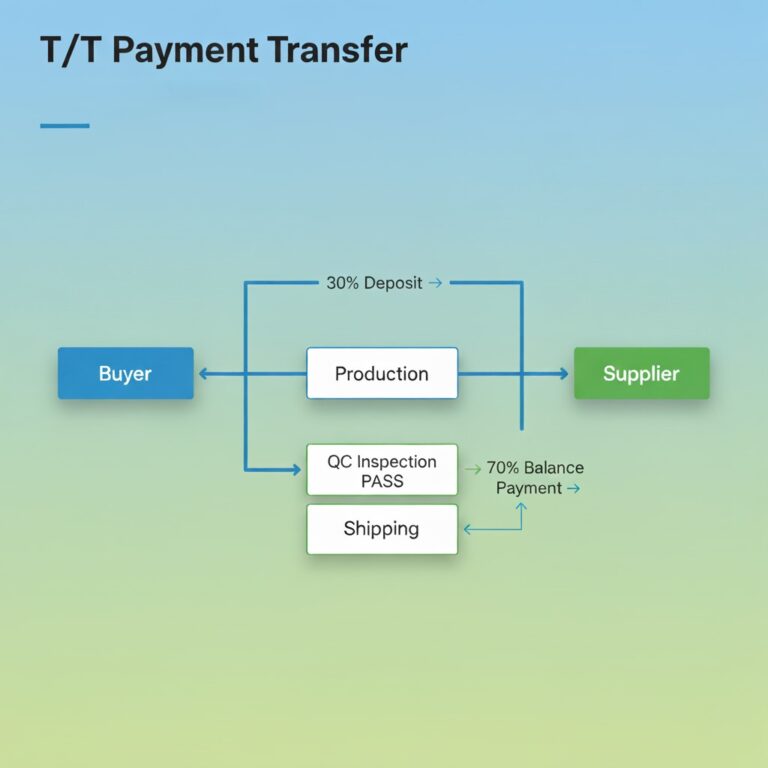

Negotiation in Vietnam is often relationship-driven. Always formalize the agreement with a comprehensive, bilingual Manufacturing Agreement. It should clearly outline all specifications, pricing, timelines, quality standards, and penalties for delays. A common payment structure is a 30-50% deposit and the balance upon completion, often after a successful quality inspection.

Step 5: Production & Monitoring

Once you’ve paid the deposit, production begins. Regular communication is key to preventing misunderstandings. A good supplier will provide you with updates and photos at key production milestones.

Step 6: Quality Control (QC) & Inspection

This is your insurance policy. Never ship goods without a thorough inspection. Professional QC is typically performed based on AQL (Acceptable Quality Limit) standards. The key inspection stages are During Production Inspection (DPI), Pre-Shipment Inspection (PSI), and Container Loading Check (CLC).

Performing on-site QC is non-negotiable for ensuring quality. For businesses unable to travel frequently, having a local partner to act as your eyes and ears is invaluable.

Step 7: Logistics & Shipping

Your product has passed inspection—now it’s time to bring it home. Understanding Incoterms is essential. FOB (Free On Board) is the most common and recommended term for SMEs, where the supplier is responsible for getting the goods loaded onto the ship at the Vietnamese port. You will need a reliable freight forwarder to manage the rest of the journey.

Your Journey Starts Here

Sourcing from Vietnam is a journey that requires due diligence, clear communication, and robust quality control. By following this 7-step process, you can avoid common mistakes and build a resilient, profitable supply chain.

Ready to explore your sourcing opportunities in Vietnam without the guesswork? Contact the expert team at EQSource today for a free, no-obligation consultation to discuss your project.