The single biggest fear for any first-time importer is sending thousands of dollars overseas and receiving a container full of defective, unsellable products. This fear can be managed and overcome with one thing: a robust Quality Control (QC) process.

QC isn’t a single event; it’s a series of checkpoints designed to catch issues early and verify quality before you make your final payment. Here is a beginner’s guide to the essential 3-stage QC process.

Stage 1: Pre-Production Check (PPC)

Also known as “Incoming Quality Control” (IQC), this happens before mass production begins. The goal is to verify that the raw materials and components that the factory will use meet your specifications.

- Why it’s important: It prevents problems at the source. If the factory starts with the wrong color fabric or incorrect grade of steel, the entire production run will be flawed.

- How it’s done: An inspector checks the raw materials against your spec sheet and the approved “golden sample.”

Stage 2: During Production Inspection (DPI or DUPRO)

This inspection is conducted when 20-50% of your order has been produced. It is an early warning system to ensure the production process is running correctly and that quality standards are being met.

- Why it’s important: It allows you to catch and correct any systematic issues before they affect the entire order, saving significant time and money compared to fixing everything at the end.

- How it’s done: An inspector pulls the first finished products from the line and compares them against the golden sample and specifications. They also check the factory’s internal QC processes.

Stage 3: Pre-Shipment Inspection (PSI or FRI)

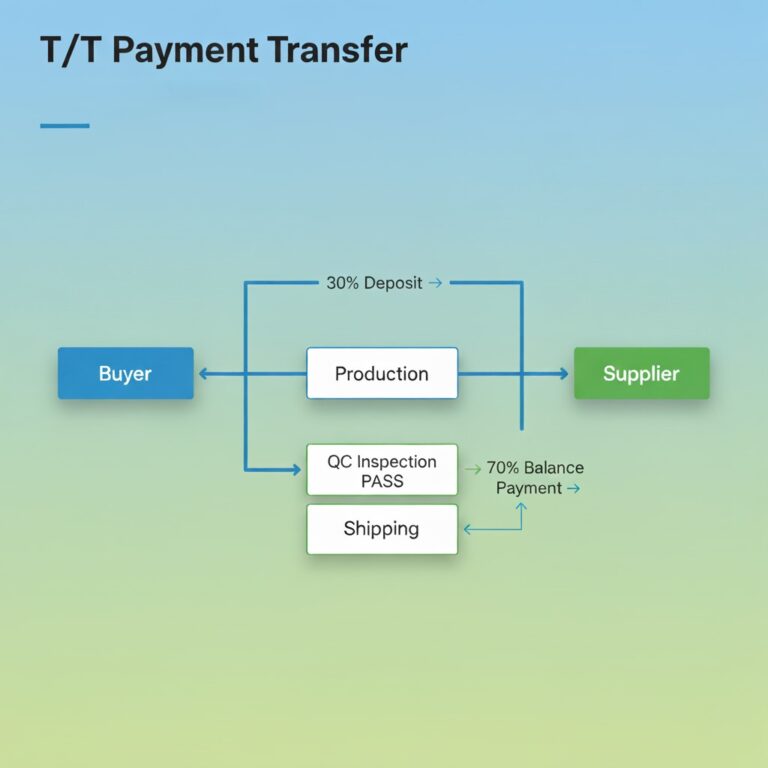

This is the most common and arguably the most critical inspection. It takes place when 100% of the goods are produced and at least 80% are fully packaged. The PSI is your final chance to see the quality of your order before it is shipped and before you make your final payment.

- Why it’s important: It provides a final, comprehensive assessment of your order’s quality, quantity, and packaging. The report from this inspection is what you will use to approve the shipment and release your final payment.

- How it’s done: An inspector uses a statistical sampling method (based on AQL standards) to pull a random selection of products. They perform a series of checks for visual defects, functionality, safety, and packaging.

For businesses that cannot be physically present in Vietnam, implementing this 3-stage process is nearly impossible alone. This is the core function of a sourcing agent: to act as your local, expert “boots on the ground,” managing these inspections to ensure your standards are met.

You Can’t Sell What You Can’t Inspect

Never assume quality. A structured QC process is not an optional extra; it is a fundamental part of a successful sourcing strategy. By implementing these three key checkpoints, you can dramatically reduce your risk, ensure you receive the product you paid for, and build a reliable, long-term relationship with your supplier.

Need reliable, on-site QC for your Vietnam production? EQSource offers a full suite of inspection services, from pre-production to container loading. Contact us to secure your quality.